Chip Seal Durability

What We Do

List of Jobs

During our

We Install Your Ideas

We will show you the color options and add a great look to your driveway.

Our Chip Seals Durability

Sometimes referred to as oil stone or tar and chip driveways or chip seal. Regardless of what you call it, we provide this service of chip sealing in Eastern Massachusetts, Southern New Hampshire, and Southern Maine. This process has long been utilized by homeowners and government agencies to extend their pavements life expectancy. The chip seal gets its durability from adding another layer of asphalt cement and bonding a hard rock layer on top of it. Our focus is on driveways and paths were the property owner want the look of a stone surface but will not get messed up by car and foot traffic.

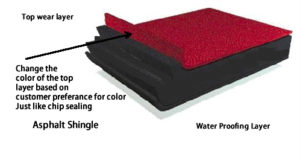

Chip Seal is Like Roofing Shingles

A shingle is a two-layer system like a chip seal. Roofing shingles consist of waterproof tar paper with embedded granules. These granules protect the roof from both abrasion and also break down in the sunlight from ultraviolet rays. The selection of the specific color of the granules embedded in the roofing shingle also provides a decorative choice the same a chip sealing does on a driveway.

A shingle is a two-layer system like a chip seal. Roofing shingles consist of waterproof tar paper with embedded granules. These granules protect the roof from both abrasion and also break down in the sunlight from ultraviolet rays. The selection of the specific color of the granules embedded in the roofing shingle also provides a decorative choice the same a chip sealing does on a driveway.

Tar and chip sealing is like the grit on shingles. It is the same thing on a driveway just a different application of a concept. The asphalt cement is placed to help waterproof the base asphalt and provide a durable surface for foot and vehicle traffic. Then the rock chips are embedded in an asphalt glue that also provides a colored and textured driveway.

The stone that is used in chip sealing is a key factor in the end products durability. Factors in stone selection are several things. Some stones are harder than another. Some stone tends to have a grain to them, so they break down easily with vehicle traffic and tires being turned when the car is not moving. Naturally, these are not used on our projects even though they may look nice they will not hold up over time and traffic. Sizing of the stone is done carefully so the thickness of the liquid asphalt will consistently hold the stone but not cover it. The shape of the stone is important for good bonding to the asphalt binder. Crushed stone is angular, blocky and rough from the crushing process. These factors help in good bonding with the asphalt binder. In comparison selecting stone that is rounded river rock would create rounded sockets trying to grip the rock in place. It would be like trying to hold marbles in place compared to chocolate chips.

Asphalt Binder

Control over the source is one of our advantages. With control of the material from the terminal to the job, there is no fooling around with the blend or mix of asphalt cement provided at the job site. Bulk material handling of the asphalt is done in our own trucks and with the fleet, we have traveling to get the best material for the job is what we do. We do this for large interstate paving projects and also for a homeowner that wants a great looking driveway to accent the property. Matching the asphalt cement to the stone, applying the right amount and rolling the stone into the asphalt are ways the asphalt binder affects the durability.

Stone Color

A single source of stone is what keeps the color uniform. We have developed a number of select sources that are durable and consistent. The color of the stone is what provides the finished products look. It is like adding frosting on the cake.

For a good looking durable driveway call us at 1-781-254-2773